V-type ball valve is a kind of core seat with metal, or metal on ptfe seal with rotary ball valve, it will be the best control characteristics of the ball valve and butterfly valve combined into one, can be used as a control valve, and can be cut off to cut off the valve. Its main features are:

(1) an integral body without any union, so it is not affected by pipe or bolt stress, and because the body has no union, the pressure-resistant shell is not affected by "sudden change" in pressure;

(2) with a v-shaped valve body, even in the case of small flow or high viscosity medium, but also in the whole range of measurement, to ensure the accuracy of control;

(3) leakproof durable seat lined with PTFE cup or O ring with stainless steel inner core at outer diameter, seat made of tungsten cobalt carbide with large section, further enhanced seat structure by an alloy corrugated spring;

(4) when the valve is closed, v-shaped gap between wedge and seat shearing action, and both have the function of self-cleaning and can prevent the ball core is stuck, especially suitable for the pipeline scaling or containing fibers and particles frozen solid occasions v-shaped ball valve is suitable for Class150 ~ 600, PN1.6 ~ 10.0 MPa, the working temperature of 200 ℃ or less of a variety of piping, used to adjust the medium inside the pipeline pressure and flow rate. Choose different materials, can be respectively applicable to water, steam, oil, nitric acid, acetic acid, oxidizing media, urea and other media. Because there is no clearance between the valve spool and seat rotation, so has a great shear force and self-cleaning performance, especially suitable for containing fiber or small solid particles suspension and solid particle control. Therefore, this product can be widely used in petroleum, chemical, papermaking, electric power, metallurgy, pharmaceutical, environmental protection and other industrial departments of automatic control system.

The main features

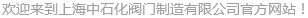

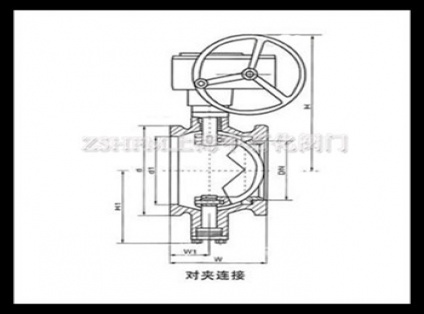

1, compact structure, small volume, vertical horizontal installation and other advantages.

2, with excellent regulation characteristics: v-type ball valve has an approximate percentage of the natural flow characteristics and up to 300:1 adjustable ratio. Therefore, the v-valve can provide precise control over a wide range of variation.

3, maximum flow volume: due to its streamlined shape and full right Angle rotation control, so that the maximum volume is particularly high, the flow capacity is particularly large, the flow resistance is small, so you can use a smaller more economical and practical valve size.

4, v-type ball valve with double bearing structure, high mechanical stability, low starting torque, ensure that the valve has excellent sensitivity and induction speed.

5, maximum reliability (safety) : the valve body as a whole, durable, operation is not affected by pipe pressure, and can avoid leakage of the valve body.

6. Superior sealing of metal seat: v-type ball valve adopts movable metal seat, self-compensation function, superior sealing performance and long service life. In the flow direction, leakage quantity ≤10-6× rated flow coefficient.

7, super shear ability: v-type ball valve adopts a metal hard seal structure, v-type ball valve core and metal seat in the process of rotation, v-type notch and seat produce a strong shear force can cut off fiber and other impurities, and has a self-cleaning function, to avoid the valve stuck phenomenon.

8, the company can be selected with the production of pneumatic, electric, and pneumatic control type, electric control type. For details, please refer to the actuator and regulator parts of this site.

Scope of use: the product can be used in petroleum, chemical and other industries.

Products conform to the standard: GB/T 12237.

(1) an integral body without any union, so it is not affected by pipe or bolt stress, and because the body has no union, the pressure-resistant shell is not affected by "sudden change" in pressure;

(2) with a v-shaped valve body, even in the case of small flow or high viscosity medium, but also in the whole range of measurement, to ensure the accuracy of control;

(3) leakproof durable seat lined with PTFE cup or O ring with stainless steel inner core at outer diameter, seat made of tungsten cobalt carbide with large section, further enhanced seat structure by an alloy corrugated spring;

(4) when the valve is closed, v-shaped gap between wedge and seat shearing action, and both have the function of self-cleaning and can prevent the ball core is stuck, especially suitable for the pipeline scaling or containing fibers and particles frozen solid occasions v-shaped ball valve is suitable for Class150 ~ 600, PN1.6 ~ 10.0 MPa, the working temperature of 200 ℃ or less of a variety of piping, used to adjust the medium inside the pipeline pressure and flow rate. Choose different materials, can be respectively applicable to water, steam, oil, nitric acid, acetic acid, oxidizing media, urea and other media. Because there is no clearance between the valve spool and seat rotation, so has a great shear force and self-cleaning performance, especially suitable for containing fiber or small solid particles suspension and solid particle control. Therefore, this product can be widely used in petroleum, chemical, papermaking, electric power, metallurgy, pharmaceutical, environmental protection and other industrial departments of automatic control system.

The main features

1, compact structure, small volume, vertical horizontal installation and other advantages.

2, with excellent regulation characteristics: v-type ball valve has an approximate percentage of the natural flow characteristics and up to 300:1 adjustable ratio. Therefore, the v-valve can provide precise control over a wide range of variation.

3, maximum flow volume: due to its streamlined shape and full right Angle rotation control, so that the maximum volume is particularly high, the flow capacity is particularly large, the flow resistance is small, so you can use a smaller more economical and practical valve size.

4, v-type ball valve with double bearing structure, high mechanical stability, low starting torque, ensure that the valve has excellent sensitivity and induction speed.

5, maximum reliability (safety) : the valve body as a whole, durable, operation is not affected by pipe pressure, and can avoid leakage of the valve body.

6. Superior sealing of metal seat: v-type ball valve adopts movable metal seat, self-compensation function, superior sealing performance and long service life. In the flow direction, leakage quantity ≤10-6× rated flow coefficient.

7, super shear ability: v-type ball valve adopts a metal hard seal structure, v-type ball valve core and metal seat in the process of rotation, v-type notch and seat produce a strong shear force can cut off fiber and other impurities, and has a self-cleaning function, to avoid the valve stuck phenomenon.

8, the company can be selected with the production of pneumatic, electric, and pneumatic control type, electric control type. For details, please refer to the actuator and regulator parts of this site.

Scope of use: the product can be used in petroleum, chemical and other industries.

Products conform to the standard: GB/T 12237.

Copyright All © ZSHFM