Q61F high pressure welding ball valve all parts are forging, the use of lower type valve stem, equipment inverted sealing structure, the use of inlaid valve seat, behind the valve seat equipment o-ring, to ensure that the medium leak, sealing surface using nylon 1010, its friction coefficient is usually pbabel 1/3, so it is a natural sliding material. But the bending strength and impact strength and higher ductility, and the same as metal.

Instructions for ordering:

1. If there is no selected model, please provide detailed parameters, such as medium, temperature, pressure, caliber, material, etc., and our technicians will select the model for you

Ii. If the selected model is available, please provide it according to the selected model

Non-standard products shall be provided with samples or confirmed by drawings

Note: the information is for reference only, or may not be complete, so we apologize for any inconvenience caused to you. The company can be selected according to different requirements and parameters. The company has a variety of sizes of caliber, pressure, different materials, connection mode, drive mode, to meet the needs of various types of valves. Please contact 021-6651 8677 or consult online.

|

适用介质 |

型号 |

阀体 |

球体、阀杆 |

手柄 |

密封圈 |

垫片、填料 |

|

水、蒸汽、油品 |

Q61N-16/320C |

A105、45 |

1Cr18/1Cr18Ni9Ti |

铸铁WCB |

聚四氟乙稀PTFE增强聚四氟乙烯VUILUK PTFE |

聚四氟乙烯PTFE对位聚笨PPL |

|

硝酸类 |

Q61N-16/320P |

304/1Cr18Ni9Ti |

304/1Cr18Ni9Ti |

|||

|

醋酸类 |

Q61N-16/320R |

316/1Cr18Ni12Mo2TI |

316/Cr18Ni12Mo2Ti |

适用温度:-20~232℃~350℃

焊接类型:对焊(BW)、承插焊(SW)

|

型号 |

Q41N-320 |

Q61N-160 |

Q61N-320 |

|

公称压力 PN(MPa) |

32.0 |

16.0 |

32.0 |

|

试验压力(Mpa) |

24.0 |

48.O |

24.0 |

|

密封(液) |

35.2 |

17.6 |

35.2 |

|

型号 |

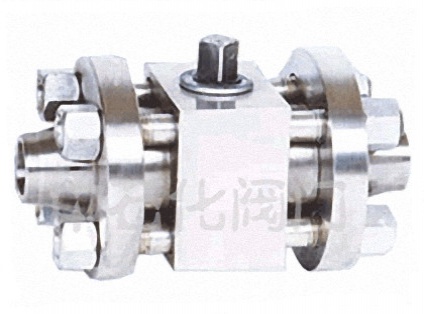

公称通径 |

尺寸(mm) |

|||||

|

L |

L1 |

D |

D1 |

H |

L0 |

||

|

Q61F N-160 |

10 |

150 |

60 |

90 |

18 |

68 |

220 |

|

15 |

170 |

70 |

100 |

23 |

62 |

220 |

|

|

20 |

191 |

81 |

110 |

29 |

75 |

250 |

|

|

25 |

205 |

985 |

115 |

36 |

80 |

250 |

|

|

32 |

230 |

110 |

150 |

43 |

96 |

300 |

|

|

40 |

260 |

120 |

170 |

49 |

111 |

400 |

|

|

50 |

330 |

140 |

200 |

61 |

128 |

400 |

|

|

65 |

360 |

150 |

220 |

80 |

180 |

500 |

|

|

80 |

380 |

160 |

270 |

105 |

200 |

600 |

|

|

100 |

430 |

188 |

320 |

118 |

245 |

800 |

|

|

型号 |

公称通径 |

尺寸(mm) |

气动装置 |

|||||

|

L |

L1 |

D |

D1 |

H |

L0 |

|||

|

Q661F N-160 |

10 |

150 |

60 |

90 |

18 |

211 |

255 |

QD60 |

|

15 |

170 |

70 |

100 |

23 |

293 |

348 |

QD100 |

|

|

20 |

191 |

81 |

110 |

29 |

297 |

348 |

QD100 |

|

|

25 |

205 |

95 |

115 |

36 |

303 |

348 |

QD100 |

|

|

32 |

230 |

110 |

150 |

43 |

456 |

520 |

QD150 |

|

|

40 |

260 |

120 |

170 |

49 |

463 |

520 |

QD150 |

|

|

50 |

330 |

140 |

200 |

61 |

478 |

520 |

QD150 |

|

|

65 |

360 |

150 |

225 |

80 |

180 |

500 |

- |

|

|

80 |

380 |

160 |

270 |

105 |

200 |

600 |

- |

|

|

100 |

430 |

188 |

320 |

118 |

245 |

800 |

- |

|

2、采用下装式阀杆,设置倒密封结构,确保填料处可靠密封及防止阀杆脱出。

3、采用镶嵌式阀座。阀座背后设置O型圈,确保介质不外漏。