Cooling type temperature control valve is a kind of driving without external energy, depending on the medium itself was transferred energy as power source and medium temperature change, according to a predetermined set value for energy-saving automatic control device. It sets detection, control, implementation of many functions in a valve, from an independent instrumentation control system. The product is composed of low flow resistance (single seat valve, sleeve) composition, temperature and equilibrium temperature setting mechanism, its characteristics are: 1, without additional energy saving control system of power equipment, low cost, suitable for explosive environment; 2, simple structure, small maintenance workload, set point can be 3; adjustable wide range, convenient for the user to adjust continuously in the range of set value; 4, a temperature overload protection device, safe and reliable; the pressure balancing mechanism 5, the valve, the valve is sensitive and accurate control, allowing a large pressure difference. Because the product without external energy, has the advantages of simple structure, convenient use, less maintenance workload, especially suitable for city heating, heating and power supply, gas supply and no need to control the liquid and gas. According to foreign reports, the city heating, heating system using the product, energy efficiency increased by 40% 30%- than before, the effect is significant.

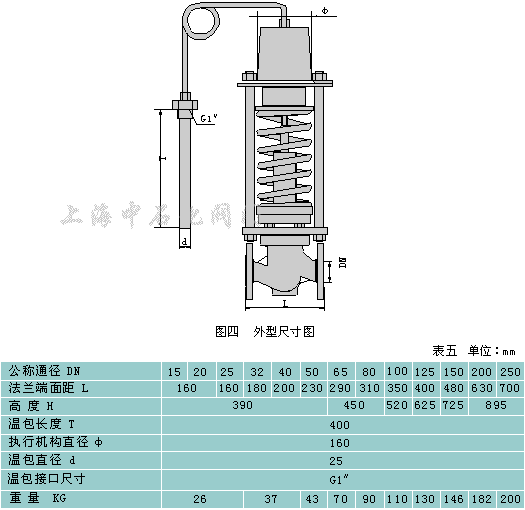

Note: parameters for reference only, or incomplete. Valve can be selected according to the requirements of different pressure, material, caliber, drive, etc.. Specific call contact or online consultation.

Note: parameters for reference only, or incomplete. Valve can be selected according to the requirements of different pressure, material, caliber, drive, etc.. Specific call contact or online consultation.

Copyright All © ZSHFM