Product [folder type multi-level] details:

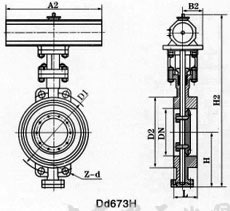

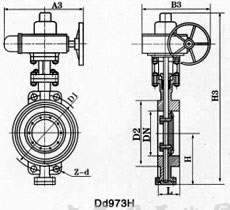

Product model:D673H

Product Name: clip type multi layer pneumatic clamping type hard seal butterfly valve

Product features: multi-level metal hard sealing butterfly valve, multi-level sealing butterfly valve, metal hard seal butterfly valve

|

Part name |

Material Science |

|

valve body |

Cast steel, stainless steel, alloy steel, chromium molybdenum steel |

|

Disc |

Cast steel, alloy steel, stainless steel, chrome molybdenum steel |

|

Seal ring |

Stainless steel and high temperature resistant asbestos board into a multi-level |

|

The stem |

2Cr13、1Cr13Stainless steel, chrome molybdenum steel |

|

Bearing |

Austenitic stainless steel, 304 nitriding |

|

filler |

Flexible graphite |

product mix:

Multi level hard sealing butterfly valve series products, our company's new development of long-life, energy-saving butterfly valve. The structure adopts three dimensional eccentric principle design, the seat adopts hard and soft seal compatible multi-level structure, exquisite processing, advanced technology. This product consists of valve body, butterfly plate, multi-level valve seat, valve stem, transmission mechanism and other major components。

三、Characteristic:

Because this product is used in valve design principle of three-dimensional space trajectory eccentric, the sealing surface of the ideal, the sealing between without friction and interference, and the sealing material selection properly, so that the valve sealing performance, corrosion resistance, high temperature resistance and wear resistance has been a reliable guarantee.

Its main features are as follows:

1、Small opening torque, flexible and convenient, energy saving;

2、Three dimensional eccentric structure, so that the more close the butterfly plate, the sealing performance is reliable, to achieve no leakage。

3、High pressure resistance, corrosion resistance, wear resistance, long service life, etc.

四、Pneumatic clamping hard seal butterfly valve Dd3/6/973H-16/25C.P.R.V size parameters:

|

Nominal diameter |

Structure length (standard value) |

Dimensions (reference values) |

Connection dimensions (standard values) |

|||||||||||||

|

H |

Dd373H |

Dd673H |

Dd973H |

PN0.6MPa |

PN1.0MPa |

|||||||||||

|

millimeter |

inch |

L |

H1 |

A1 |

B1 |

H2 |

A2 |

B2 |

H3 |

A3 |

B3 |

D1 |

Z-d |

D1 |

Z-d |

|

|

50 |

2 |

43 |

112 |

350 |

180 |

200 |

625 |

245 |

72 |

530 |

250 |

255 |

110 |

4-14 |

125 |

4-18 |

|

65 |

2 1/2 |

46 |

115 |

370 |

180 |

200 |

625 |

245 |

72 |

530 |

250 |

255 |

130 |

4-14 |

145 |

4-18 |

|

80 |

3 |

64 |

120 |

380 |

180 |

200 |

645 |

245 |

72 |

565 |

250 |

255 |

150 |

4-18 |

160 |

8-18 |

|

100 |

4 |

64 |

138 |

420 |

180 |

200 |

675 |

355 |

92 |

600 |

250 |

255 |

170 |

4-18 |

180 |

8-18 |

|

125 |

5 |

70 |

164 |

460 |

180 |

200 |

715 |

355 |

92 |

640 |

250 |

255 |

200 |

8-18 |

210 |

8-18 |

|

150 |

6 |

76 |

175 |

555 |

270 |

280 |

800 |

355 |

92 |

705 |

300 |

315 |

225 |

8-18 |

240 |

8-22 |

|

200 |

8 |

89 |

215 |

780 |

400 |

425 |

850 |

250 |

170 |

775 |

300 |

315 |

280 |

8-18 |

295 |

8-22 |

|

250 |

10 |

114 |

243 |

840 |

400 |

425 |

925 |

250 |

170 |

945 |

300 |

315 |

335 |

12-18 |

350 |

12-22 |

|

300 |

12 |

114 |

285 |

995 |

450 |

560 |

1035 |

450 |

220 |

1070 |

300 |

315 |

395 |

12-22 |

400 |

12-22 |

|

350 |

14 |

127 |

320 |

1050 |

450 |

560 |

1070 |

450 |

220 |

1140 |

300 |

315 |

445 |

12-22 |

460 |

16-22 |

|

400 |

16 |

140 |

350 |

1220 |

535 |

580 |

1190 |

450 |

220 |

1210 |

300 |

315 |

495 |

16-22 |

515 |

16-26 |

|

450 |

18 |

152 |

350 |

1280 |

535 |

580 |

1250 |

650 |

280 |

1335 |

575 |

714 |

550 |

16-22 |

565 |

20-26 |

|

500 |

20 |

152 |

380 |

1365 |

535 |

580 |

1290 |

650 |

280 |

1415 |

575 |

714 |

600 |

20-22 |

620 |

20-26 |

|

600 |

24 |

154 |

435 |

1460 |

570 |

660 |

1455 |

850 |

380 |

1605 |

656 |

810 |

705 |

20-26 |

725 |

20-30 |

|

700 |

28 |

165 |

480 |

1520 |

750 |

550 |

1585 |

850 |

380 |

1844 |

656 |

810 |

810 |

24-26 |

840 |

24-30 |

|

800 |

32 |

190 |

530 |

1710 |

750 |

550 |

1700 |

1250 |

380 |

2040 |

656 |

810 |

920 |

24-30 |

950 |

24-33 |

|

900 |

36 |

203 |

595 |

1810 |

750 |

550 |

1965 |

1250 |

380 |

2255 |

785 |

863 |

1020 |

24-30 |

1050 |

28-33 |

|

1000 |

40 |

216 |

650 |

1900 |

900 |

750 |

2015 |

1250 |

380 |

2380 |

785 |

863 |

1120 |

28-30 |

1160 |

28-36 |

|

1200 |

48 |

254 |

775 |

2280 |

1000 |

925 |

2250 |

1250 |

380 |

2640 |

785 |

863 |

1340 |

32-33 |

1380 |

32-39 |

|

1400 |

56 |

279 |

870 |

2450 |

1000 |

925 |

- |

- |

- |

- |

- |

- |

1560 |

36-36 |

1590 |

36-42 |

|

1600 |

64 |

440 |

1000 |

2730 |

1000 |

925 |

- |

- |

- |

3156 |

- |

- |

1760 |

40-36 |

1820 |

40-48 |

|

1800 |

72 |

490 |

1110 |

3020 |

1100 |

980 |

- |

- |

- |

3421 |

- |

- |

1970 |

44-39 |

2020 |

44-48 |

|

2000 |

80 |

540 |

1250 |

3270 |

1100 |

980 |

- |

- |

- |

3685 |

- |

- |

2180 |

48-42 |

2230 |

48-48 |

五、Dd3/6/973H-16/25C.P.R.V parameter of clamping multi level metal seal butterfly valve:

|

Nominal diameter |

Structure length (standard value) |

Dimensions (reference values) |

Connection dimensions (standard values) |

||||||||||||||

|

H |

Dt373H |

Dt673H |

D973H |

PN0.6MPa |

PN1.0MPa |

||||||||||||

|

millimeter |

inch |

L |

H1 |

A1 |

B1 |

H2 |

A2 |

B2 |

H3 |

A3 |

B3 |

D1 |

Z-d |

D1 |

Z-d |

||

|

50 |

2 |

43 |

112 |

350 |

180 |

200 |

625 |

245 |

72 |

530 |

250 |

255 |

125 |

4-14 |

125 |

4-18 |

|

|

65 |

2 1/2 |

46 |

115 |

370 |

180 |

200 |

625 |

245 |

72 |

530 |

250 |

255 |

145 |

4-14 |

145 |

8-18 |

|

|

80 |

3 |

64 |

120 |

380 |

180 |

200 |

645 |

245 |

72 |

565 |

250 |

255 |

160 |

8-18 |

160 |

8-18 |

|

|

100 |

4 |

64 |

138 |

420 |

180 |

200 |

675 |

355 |

92 |

600 |

250 |

255 |

180 |

8-18 |

190 |

8-22 |

|

|

125 |

5 |

70 |

164 |

460 |

180 |

200 |

715 |

355 |

92 |

640 |

250 |

255 |

210 |

8-18 |

220 |

8-26 |

|

|

150 |

6 |

76 |

175 |

555 |

270 |

280 |

800 |

355 |

92 |

705 |

300 |

315 |

240 |

8-22 |

250 |

8-26 |

|

|

200 |

8 |

89 |

215 |

780 |

400 |

425 |

850 |

250 |

170 |

775 |

300 |

315 |

295 |

12-22 |

310 |

12-26 |

|

|

250 |

10 |

114 |

243 |

840 |

400 |

425 |

925 |

250 |

170 |

945 |

300 |

315 |

355 |

12-26 |

370 |

12-30 |

|

|

300 |

12 |

114 |

285 |

995 |

450 |

560 |

1035 |

450 |

220 |

1070 |

300 |

315 |

410 |

12-26 |

430 |

16-30 |

|

|

350 |

14 |

127 |

320 |

1050 |

450 |

560 |

1070 |

450 |

220 |

1140 |

300 |

315 |

470 |

16-26 |

490 |

16-33 |

|

|

400 |

16 |

140 |

350 |

1220 |

535 |

580 |

1190 |

450 |

220 |

1210 |

300 |

315 |

525 |

16-30 |

550 |

16-36 |

|

|

450 |

18 |

152 |

350 |

1280 |

535 |

580 |

1250 |

650 |

280 |

1335 |

575 |

714 |

585 |

20-30 |

600 |

20-36 |

|

|

500 |

20 |

152 |

380 |

1365 |

535 |

580 |

1290 |

650 |

280 |

1415 |

575 |

714 |

650 |

20-33 |

660 |

20-36 |

|

|

600 |

24 |

154 |

435 |

1460 |

570 |

660 |

1455 |

850 |

380 |

1605 |

656 |

810 |

770 |

20-36 |

770 |

20-39 |

|

|

700 |

28 |

165 |

480 |

1520 |

750 |

550 |

1585 |

850 |

380 |

1844 |

656 |

810 |

840 |

24-26 |

875 |

24-42 |

|

|

800 |

32 |

190 |

530 |

1710 |

750 |

550 |

1700 |

1250 |

380 |

2040 |

656 |

810 |

950 |

24-39 |

990 |

24-48 |

|

|

900 |

36 |

203 |

595 |

1810 |

750 |

550 |

1865 |

1250 |

380 |

2255 |

785 |

863 |

1050 |

28-39 |

1090 |

28-48 |

|

|

1000 |

40 |

216 |

650 |

1900 |

900 |

750 |

2015 |

1250 |

380 |

2380 |

785 |

863 |

1170 |

28-42 |

1210 |

28-56 |

|

|

1200 |

48 |

254 |

775 |

2280 |

1000 |

925 |

2250 |

1250 |

380 |

2640 |

785 |

863 |

1390 |

32-48 |

1420 |

32-56 |

|

|

1400 |

56 |

279 |

870 |

2450 |

1000 |

925 |

- |

- |

- |

2886 |

- |

- |

1590 |

36-48 |

1640 |

36-62 |

|

|

1600 |

64 |

440 |

1000 |

2730 |

1000 |

925 |

- |

- |

- |

3156 |

- |

- |

1820 |

40-56 |

1860 |

40-62 |

|

|

1800 |

72 |

490 |

1110 |

3020 |

1100 |

980 |

- |

- |

- |

3421 |

- |

- |

2020 |

44-56 |

2070 |

44-70 |

|

|

2000 |

80 |

540 |

1250 |

3270 |

1100 |

980 |

- |

- |

- |

3685 |

- |

- |

2230 |

48-62 |

2300 |

48-70 |

|

四、Dd3/6/973H-40C.P.R.V parameter of clamping multi level metal seal butterfly valve:

|

Nominal diameter |

Structure length (standard value) |

Dimensions (reference values) |

Connection dimensions (standard values) |

|||||||||||

|

H |

Dd343H |

Dd643H |

Dd943H |

PN4.0MPa |

||||||||||

|

millimeter |

inch |

L |

H1 |

A1 |

B1 |

H2 |

A2 |

B2 |

H3 |

A3 |

B3 |

D1 |

Z-d |

|

|

50 |

2 |

43 |

112 |

350 |

180 |

200 |

- |

- |

- |

530 |

250 |

255 |

125 |

4-18 |

|

65 |

2 1/2 |

46 |

115 |

370 |

270 |

280 |

625 |

250 |

170 |

550 |

250 |

255 |

145 |

8-18 |

|

80 |

3 |

64 |

120 |

380 |

270 |

280 |

625 |

250 |

170 |

565 |

250 |

255 |

160 |

8-18 |

|

100 |

4 |

64 |

138 |

420 |

270 |

280 |

645 |

250 |

170 |

600 |

250 |

255 |

190 |

8-22 |

|

125 |

5 |

70 |

164 |

460 |

380 |

420 |

675 |

250 |

170 |

640 |

250 |

255 |

220 |

8-26 |

|

150 |

6 |

76 |

175 |

555 |

380 |

420 |

715 |

450 |

220 |

705 |

300 |

315 |

250 |

8-26 |

|

200 |

8 |

89 |

208 |

780 |

400 |

425 |

800 |

450 |

220 |

775 |

300 |

315 |

320 |

12-30 |

|

250 |

10 |

114 |

243 |

840 |

400 |

425 |

850 |

450 |

220 |

945 |

300 |

315 |

385 |

12-33 |

|

300 |

12 |

114 |

285 |

995 |

450 |

560 |

925 |

450 |

280 |

1070 |

300 |

315 |

450 |

16-33 |

|

350 |

14 |

127 |

320 |

1050 |

450 |

560 |

1035 |

650 |

280 |

1140 |

300 |

315 |

510 |

16-36 |

|

400 |

16 |

140 |

350 |

1220 |

535 |

580 |

1070 |

650 |

280 |

1210 |

300 |

315 |

585 |

16-39 |

|

450 |

18 |

152 |

350 |

1280 |

535 |

580 |

1190 |

650 |

280 |

1335 |

575 |

714 |

610 |

20-39 |

|

500 |

20 |

152 |

380 |

1365 |

535 |

580 |

- |

- |

- |

1415 |

575 |

714 |

670 |

20-42 |

Note: flange standard:GB/T9113.1-2000 GB/T9115.1-2000

Note: the user in Table 1 H1, H2, H3 size can be based on user needs to be lengthened (long rod valve), if you need to order the special materials。

Note: Dt- represents multi layered seal structure

|

Nominal diameter |

DN(mm) |

50~1200 |

||||

|

Nominal pressure |

PN(MPa) |

0.6 |

1.0 |

1.6 |

2.5 |

4.0 |

|

Test pressure |

strength test |

0.9 |

1.5 |

2.4 |

3.75 |

6.0 |

|

|

Seal test |

0.66 |

1.1 |

1.76 |

2.75 |

4.4 |

|

|

Air tight test |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

|

permeability |

<0.1×DNmm3/s(accord withGB/T13927-92standard) |

|||||

|

Applicable temperature |

carbon steel:-29℃~425℃ Stainless steel:-40℃~600℃ |

|||||

|

Applicable medium |

Air, water, steam, gas, oil and acid, alkali, salt with weak corrosive medium。 |

|||||

|

Driving form |

Worm gear transmission, gas transmission, electric drive |

|||||

简体中文版

简体中文版 English

English